Making an Angle Jig

This handy jig holds a piece of wood at an angle.

I built it to hold bulkheads upright while I worked on fitting and measuring them on a curved bottom. This was for my SCAMP build.

It's a very simple gizmo and dimensions are not critical.

In the Scamp build, the bulkheads have to be positioned perfectly vertically on a curved bottom. It's tricky to do alone so I made this jig to hold the bulkhead in the proper position. It can be adjusted to any angle.

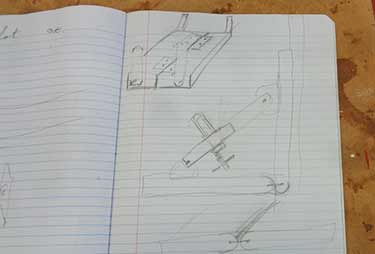

While I was in design school I was told the difference between a designer and a craftsman is that the designer works out his design on paper first while the craftsman goes directly to building and works out the design through trial and error.

In my third year of school something clicked in my brain and I started thinking through my hands and drawings. Difficult to explain but magic when it happened.

Materials

- 1 piece board 6 inch x 3/4 inch thick x 9 inches. I used a pine board but plywood would be fine. Size are approximate.

- 1 piece board 6 inch x 3/4 inch thick x 8 1/2 inches.

- A length of piano hinge at least 6 inches long and not more than 8 1/2 inches with appropriate screws. If you use regular hinges make sure they don't have any play in them otherwise your jig will not be quite as accurate.

- 4- 1 1/4" screws with pan heads and a short distance at the top with no threads.

- 4 pieces of 1/4" plywood x 5 inches x 3/4 wide

- 2 small C clamp or strong spring clamps.

Procedure

Attach the piano hinge in the centre of the boards. Make sure that the shorter board is centered on the larger one and the difference is equal on both sides.

Pre-drill a hole in the end of each of the 4 short plywood pieces. I roughtly rounded the corners using sandpaper.

Insert a screw in each of the 4 tabs and screw to the end.

These screws have pan heads and don't have threads at the very top. This allows the little tab to rotate freely around the screw.

Drill pilot holes in the 4 edges of the boards

Screw the 4 tabs into the ends of the boards and tighten snug but not so tight that the tabs can't move.

You should now be able to slide the tabs against each other and position them using a clamp.

Because the 2 boards are not quite the same length the little tabs can slide against each other.

It would be possible to use a router and make a slot on each of the little tabs and use a bolt with a butterfly nut to adjust the angle but this is a quick and dirty jig to help specifically in my SCAMP build. If they turn out to be useful I'll build nicer ones.

I've used C clamps because they can be tightened quite a lot. Good spring clamps would work too I think.

I made 2 jigs while I was at it. Not much extra work and some of the bulkheads are quite long and need more support.

When not in use the 2 jigs folds up in a small package.

One of the SCAMP bulkheads in the jig. I will use 2 when I use them in case the bulkhead bends. I'm using bar clamps to attach the bulkhead but I could use other clamps here. If the bulkheads were heavy I might add a brick onto the base of the jig.

I use also a square jig. It is an accurate 90 degrees and I use it when I'm assembling sides together. I can clamp boards or panels to it. I have 2 of those and I'm always reaching for them.

I try to be accurate and check my information, but mistakes happen.

email me if you find mistakes, I'll fix them and we'll all benefit: ChristineTen Essential Knots

Marine Plywood Article.

Making a handmade carbon fiber mast for your sailing dinghy

DIY Launching Dolly for small boats

Making a birdsmouth mast

My sailmaking experiments

Carbon Fiber Characteristics

Making a Puddle Duck Racer

Launching a stitch and glue Apple Pie Pram that I built as a tender for my Tanzer. The plans were free

Nautical Terms explained Boat building has its own language. Here are the most common boat hull terms explained.

Fine Woodworking Jigs

Small Print

This information is for general knowledge. It's not intended to replace plans or proper instructions. If you are not comfortable using powertools get help cutting and drilling. Be safe and have fun.