Compound Lever Press

What is a compound lever press and why would I ever want to make one! The reason I made it is simple. I was interested to see how it worked. I am curious and like to experiment and play. I had the material and construction is simple.

What I will do with it is unmould soap cast in water pipe. I've been making soap and have found that the soap sticks in an unlined pipe, and lining a pipe is fiddly. I tried the press and it pushes the soap nicely out.

A second use is to make biomass briquettes to burn in the fireplace and experiment with the woodgas stoves I made earlier.

A compound lever press is a press that combines the action of 2 or more levers to multiply the force applied.

How does the Compound Lever work

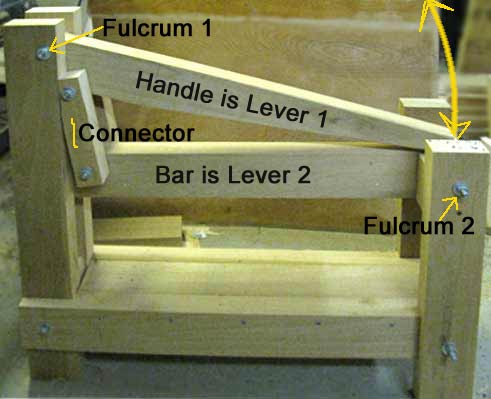

In this model there are 2 fulcrums and 2 levers. A handle goes down applying force. This force is transferred to a second lever which multiplies the force of the first lever, which in turn is multiplying the force of the human pushing on the handle.

The handle acts as the first lever. It is attached to the frame with a kickass bolt which acts as the first pivot point, the fulcrum 1. Betwee the handle and the Bar there are 2 pieces of wood whose job it is to pass on the force from the first lever to the second lever. The connector bars do not increase the mechanical advantage, they just pass on the pressure onto the Bar. Now the second lever is being pressed on by the connector bars and move down. Its fulcrum is at the opposite end.

When a force is applied by lowering the handle, the handle arcs down going through a large motion of about 25 inches. Because the connectors are close to the fulcrum they move through a smaller distance about 10 inches (but have much more force per square inch than the human pushing and applying the first force). This larger force is applied to the lever 2 which moves through the same 10 inches. Where the connector attaches to the Bar (lever 2) is equivalent to the handle of the second lever. Near the fulcrum 2 the distance moved is much smaller. At the very end it is only about .5 of an inch.

To get an idea of the multiplying of force it is useful to do the calculation. If a force of 12 pounds per square inch is applied at the handle through a height of about 25 inches by someone pressing down, the handle at the level of the connectors moves about 10 inches. 25inches/10inches is a ratio of 2.5 which is the mechanical advantage x 12 pounds = 30 pounds per square inch being applied to the lever 2. In the second lever this 30 pounds per square inch moving through 10 inches moves the lever only .5 inch. The ratio of .5/10 inches gives a mechanical advantage of 20. Thus our initial push of 12 pounds per square inch has become 600 pounds per square inch. The distance is only a fraction of the original distance applied but the force is very concentrated through the smaller distance.

Half way through the second lever moves about 5 inches and this is a useful distance. In practice I have found that the large pressure is not particularly necessary when making biomass briquettes, nor when pressing soap out of moulds. Engineers without borders claim that a briquettete requires 145 pounds per square inch of pressure. This press can do this easily.

Plans for the compound lever press

I ran across the plans for the micro compound lever press while exploring the Internet. It is offered by Engineers Without Borders and can be downloaded free from their website.

They have designed their press to be made using regular 2x4 with possibly stronger lumber for the levers and connectors if available. I used lumber I had around lef tover from making kitchen cabinet doors. It was sold as poplar and is quite strong and heavier than spruce and pine 2x4. It is also thicker than the nominal 2x4 and I had to adjust the thickness of the cuts I made. They offer 2 models. One has a diagonal brace and the second has slots in the side of the uprights of the frame. I don't know the name of the "slot" joint, maybe a rabbet? Anyway the brace or slot act to make the frame rigid.

I still need to sand and paint it or at least put some linseed oil on the press.

Demo of several different presses including the micro compound press

Demonstration by Engineers Without Borders, of pressing using different kinds of presses in making biomass briquets.

Because my lumber is much stronger than the 2x4 softwood, my press does not bend at all while being used. There is no flex anywhere.

I've tested it with a mixture of paper and sawdust and made some biomass briquettetes. Here are photos and descriptions of what I did.

I will be testing them in my woodgas stoves. once the weather warms up a bit. It's 10 below today and very snowy.

email me if you find mistakes, I'll fix them and we'll all benefit: Christine

Brickette Making

Wikipedia article on biomass briquettetes

Brickette making in Congo helps prevent Gorilla Habitat damage.

Press made from a jack, Youtube Video

Another Jack Press that makes 25 square briquettes at a time.

Another style of press from the same guy as above.

Soap Making

My Soapmaking experiments

Small Print

I don't claim to be an expert in anything. If you want to build a press be careful. Enjoy!